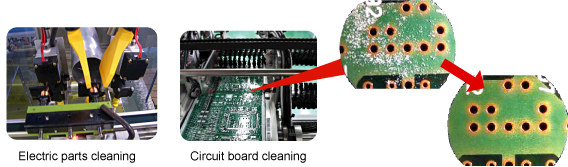

To prevent and remove the contaminationIon Air Cleaning Unit

Cleaning by ordinary air blow system would encounter static electricity problem. This static electricity is made by the friction between the air and product. Some contamination will be left sticking on the product because of static alectricity.

Ionized air by corona discharger would not perform static electricity and also remove the static electricity on the contamination. Dust-blow function has a unique function that is called "Intermittent blow system" (Patent No. 3112987). This blowing method causes shock wave and blows of the contamination.

|

Outline |

|---|---|

|

Ionized aor is produced by DC corona system. Electro magnetic valve is special type for intermittent air blow system. |

|

Merit of installing |

|

Cost saving. No drying section needed like liquid cleaning system. No drain outlet or water recycling system needed. |

|

Lineup |

|

NH-10/NH-10M Ionizing unit, electro magnetic valve and controller for intermittent air blow are installed in this unit. Connect AC power and compressed air to the unit. NH-20/NH-20M Elerctro magnetic valve is controlled by outside controller. Ion air cleaning unit is installed in the production line. NPG-500 Small & light gu type ion air cleaner * Each unit can choose flare type nozzle or bar type nozzle. |

|